Real numbers prove the ROI value of equipment maintenance software

Scheduled or preventive maintenance, as opposed to unscheduled or emergency work, has improved to over 70 percent at GeoStabilization International, according to vice president of fleet Jeff Bremer. The company tracks closely the days that its 1,000 pieces of equipment are down for repairs as a percentage of overall workdays. Bremer says reducing those expensive down days through the shift to preventive maintenance added $5 million to the company’s bottom line in the first year that B2W Maintain was fully implemented through reductions in repair costs as well as the expenses associated with lost productivity and the need for replacement or rental equipment.

Dave Pacella, fleet manager at RJV construction, estimates that the average company spends about 15 percent of revenue on maintenance costs. A strict preventive maintenance program with B2W Maintain allowed his company cut that to eight percent of revenue.

Uptime – the amount of time equipment is actually available to be deployed – is a key performance indictor for maintenance operations. Dan Corbett, equipment manager at Lancaster Development, says 65-70 percent is common for heavy construction companies. B2W Maintain helped his team achieve 95 percent uptime.

At Barriere Construction in Louisiana, uptime is above 95 percent. Director of equipment and facilities Ben Tucker says the volume of emergency work is below three percent since implementing B2W Maintain, a figure he proudly calls “world class” and “money in the bank”.

Twenty percent of all maintenance work for 250 assets at Severino Trucking was done on an emergency basis in the year before adopting B2W Maintain. Skip Brownell, who manages maintenance, and his team cut that figure to 11 percent the following year. A precise dollar value of corresponding reductions in repair costs, downtime and jobsite disruptions is hard to pinpoint, but Brownell says it is substantial.

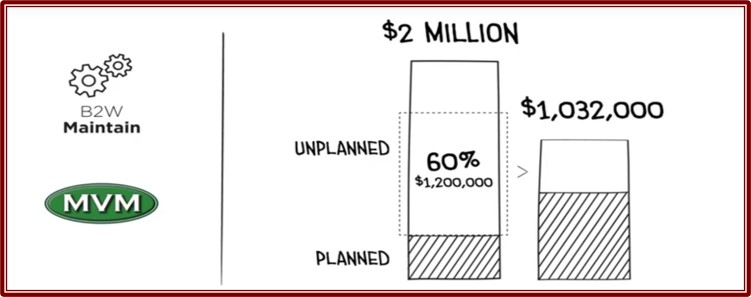

Fred Brooks at Mohawk Valley Material is more specific. He says B2W Maintain will cut maintenance costs in half, saving $1 million per year. Eighty percent of repair work at MVM used to be unplanned. The software helped the company set up and stick to preventive maintenance plans and flip that ratio completely to 80 percent planned. This short video explains the $1-million savings calculation based on the assertion by Brooks that planned maintenance is five times less costly than unplanned work.

There is another important ROI aspect to consider. These contractors, and others using B2W Maintain, have access to the data to track these KPIs easily and drive continuous improvement. That is something maintenance operations relying on paper and spreadsheets struggle to do and often give up on.

Leave a Reply

Want to join the discussion?Feel free to contribute!