Want Best-in-class Fleet Maintenance for Your Heavy Civil Construction Business?

In addition to personnel, equipment is essential to heavy civil construction operations. Keeping a fleet on the job and in safe, working order is a challenge with considerable financial risks and rewards.

Add maintenance and repair costs to the impact that out-of-commission equipment has on productivity, and the bottom line can suffer significantly. The logical solution is to put systems in place that drive preventive maintenance, maximize uptime, deliver data and increase profitability. So, how do you do that?

You Can’t Improve What You Don’t Measure

Construction companies cannot really improve equipment maintenance processes unless they first know how their current results compare to industry benchmarks. They need the right information and they need to measure performance in a consistent manner.

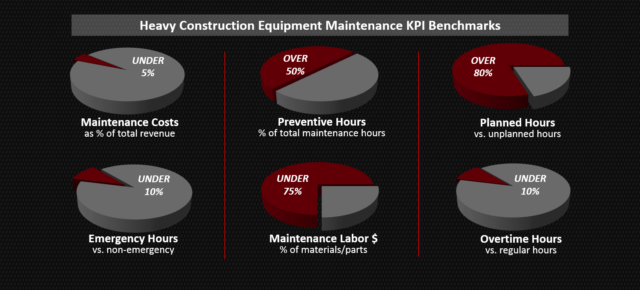

These are the top six key performance indicators for equipment maintenance that contractors should track. We also included some industry accepted targets the maintenance team should shoot for and a few additional KPIs that can also be considered.

-

- Maintenance Costs as a Percentage of Total Revenue

Some heavy civil construction companies find themselves spending 15 percent or more of total revenue on equipment maintenance costs. The best hold that number to below five percent. That’s a huge gap, and any improvements go right to bottom-line profitability.

-

- Preventive Maintenance Hours

By servicing equipment at predetermined intervals, contractors can detect and prevent failures before they occur. This saves money, increases uptime, maximizes maintenance staff efficiency and extends the life of the equipment. These intervals are based on time or use, and typical preventive actions include inspections, cleanings, lubrication, adjustments, component replacement and minor repairs. Heavy civil construction companies with effective, proactive maintenance programs should spend 50 percent or more of their maintenance labor hours on preventive work.

-

- Planned Hours vs. Unplanned Hours

With dozens or even hundreds of pieces of construction equipment in a fleet, developing and following a preventive maintenance regimen can be challenging. However, the rewards are substantial. When maintenance work is planned in advance, contractors maximize the efficiency of their mechanics and minimize disruptions to production in the field. Using maintenance labor hours as the measurement, construction companies should aim to schedule and plan 80 percent or more of work in advance.

-

- Emergency Maintenance Hours

Anyone who manages construction equipment – or owns a car, for that matter – knows that breakdowns can be inevitable, but they are also far less likely, if the asset is serviced regularly. When equipment breaks down unexpectedly, productivity is impacted, and repair or replacement costs are often much higher than for routine, preventive maintenance. Maintenance managers at heavy civil construction operations should leverage preventive maintenance to hold the hours their mechanics’ spend on emergency work to below 10 percent of total hours.

-

- Maintenance Labor vs. Materials

If a construction company is optimizing the efficiency of its maintenance team, labor should account for less than 75 percent of the total parts costs. To calculate this, simply divide total maintenance labor cost by total parts cost.

-

- Mechanic Overtime Hours

More unplanned or emergency work inevitably means more overtime hours for the maintenance staff. With an effective preventive maintenance program, contractors should generally be able to hold overtime hours to below 10 percent of overall maintenance hours. Do the math, and ensure your overtime budget is being used as effectively as possible.

Additional equipment related KPIs commonly tracked by heavy construction contractors include:

- Asset uptime: the percentage of overall production time that a piece of equipment or the overall fleet is actually available to be used

- Mileage of mechanics: how many miles they drive to and from job sites to do maintenance/repairs

- Days to repair: the time it takes, on average, to complete repairs after a receiving a request or notification

- Maintenance costs as a percentage of the overall estimated replacement value of the fleet

- Schedule compliance: percentage of work orders complete on or before scheduled due date

Tracking and measuring KPIs gives contractors a clear picture of their equipment maintenance costs along with the opportunities for improvement, and specialized fleet maintenance software is part of the solution. Companies without standardized maintenance processes and those that rely on outdated and inefficient spreadsheets or paper processes often find themselves in a costly trap of spending too much on maintenance and repairs and trying to compensate for a lack of efficiency, visibility and controls by retaining more equipment, resources and inventory than they need.

An effective software solution, on the other hand, allows them to automate preventive maintenance, get more proactive and access the data they need to measure and improve performance.

Leave a Reply

Want to join the discussion?Feel free to contribute!